Different Sealing Methods for Fiber Splice Closure: 3 Essential Strategies

Equip yourself with the knowledge to choose the right fiber joint closure for any application. In this guide, we uncover the three essential strategies for enhancing your fiber networks' longevity and efficiency.

Why is the Sealing Method of a Fiber Splice Closure Important?

The sealing method of a fiber splice closure is paramount for several reasons.

Firstly, it protects against environmental hazards like moisture, dust, and debris that can damage delicate fiber optic cables. Effective sealing thus guarantees the longevity and reliability of your network.

Moreover, a correctly sealed closure maintains optimal signal performance, keeping away foreign elements that can cause signal loss or degradation, resulting in poor network performance or total failure. Thus, these methods ensure the integrity and efficiency of the fiber optic system.

By thwarting the entry of water and other contaminants, the sealing methods significantly reduce the risk of electrical hazards and short circuits, thereby enhancing the network's overall safety.

Investing in robust sealing methods for fiber splice closures is non-negotiable to ensure a secure, reliable, and high-performing fiber optic network. It safeguards the cables from external threats while maintaining signal integrity and system safety.

Understanding Heat-shrinkable Fiber Closures

Heat-shrinkable fiber splice closures use a material that contracts when heated, creating a tight seal around the fiber optic cables, protecting splice points from moisture, dirt, and mechanical damage. Known for its durability and resistance to harsh weather conditions, this method is generally reliable.

Pros

- Reliability: It offers a reliable sealing solution that maintains a firm grip for extended periods.

- Waterproof: Guarantees a watertight seal, preventing moisture and potential water damage.

- Ease of Installation: The installation process is relatively straightforward, requiring only basic training for technicians.

- Cost-Effectiveness: The manufacturing cost is lower compared to mechanical fiber closures.

Cons

- Limited Adjustability: Once sealed, it becomes challenging to access fiber cables for adjustments or maintenance.

- Time Durability: The material can become fragile over time, potentially developing cracks.

- High Maintenance Cost: Expanding fiber capacity necessitates the removal and reinstallation of the original splice closure, increasing costs and construction time.

Ideal Deployment Locations for Heat-shrinkable and Mechanical Splice Closures

Heat-Shrinkable Fiber Splice Closure: Ideal Deployment Locations

- Centralized Data Centers: Suited for environments housing centralized data systems where cables are seldom manipulated.

- Underground Networks: The airtight and watertight sealing make it ideal for underground installations.

Considerations for Deployment

- Skill Requirement: Installation demands skilled professionals, making it suitable for settings with available skilled teams.

- Static Environments: Best utilized in environments with minimal adjustments and maintenance needs.

Mechanical Fiber Splice Closure: Ideal Deployment Locations

- Distribution and Drop Segments: A viable option in segments requiring a user-friendly setup.

- Aerial Installations: Suitable for aerial installations due to its re-enterable feature, accommodating different cable types and facilitating easier maintenance.

Considerations for Deployment

- Diverse Outside Plant Environment: Offers needed versatility to house both spliced and pre-terminated cabling solutions in varied network environments.

- User-Friendly: Accommodates installation crews with less specialized skills, apt for broader network segments with a mix of expertise levels.

Conclusions

Choosing the correct sealing method involves considering factors such as installation conditions, anticipated environmental challenges, and the specific requirements of the fiber splice closure. While heat-shrinkable options offer reliability and a tight seal, they lack the flexibility and re-enterability of mechanical closures, which although flexible, can have more complex installations and are more prone to mechanical failures. Thus, a careful evaluation is crucial to maintain the integrity and longevity of fiber splice closures, ensuring optimum performance and safeguarding your network infrastructure.

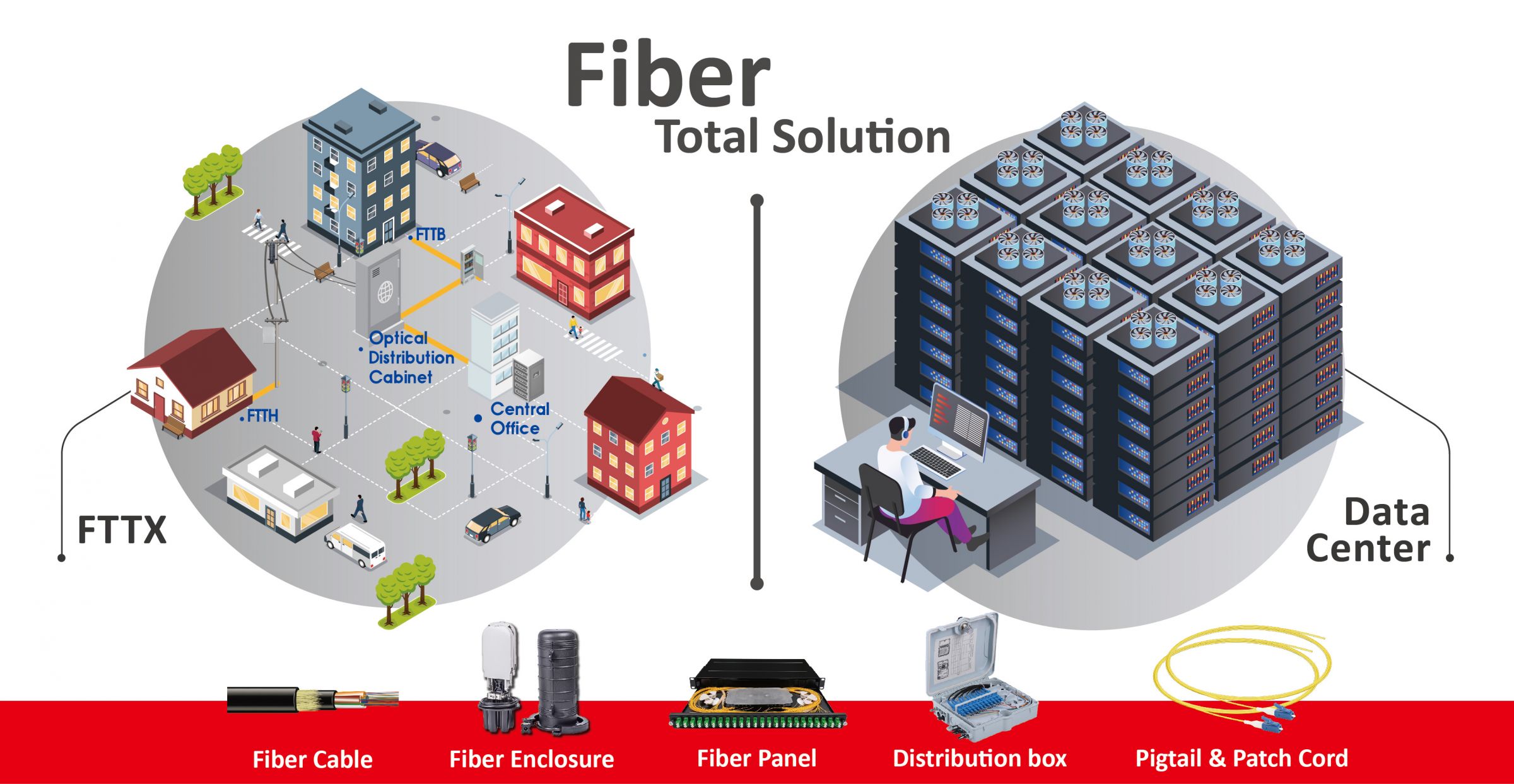

CRXCONEC: Enhancing FTTx for a Better Life

At CRXCONEC, we recognize the importance of reliable and efficient FTTx infrastructure. We are devoted to furnishing solutions that not only enhance fiber connectivity but also elevate the quality of life for individuals and businesses alike. Our array of passive components is crafted to satisfy the demands of optical networks and FTTH applications, ranging from connectors and splitters to fiber patch cords and fiber splice closures. Our goal is to provide superior products that promise peak performance and reliability.

We offer four innovative solutions:

- FTTH & ODN Solution

- Underground Application Solution

- Aerial Deployment Solution

- ODM Customized Solution

Know more our FTTH cabling solution!Contact us by leaving a message through the below form!

- File DownloadRelated SolutionsRelated Products

Different sealing methods of fiber closure: 3 Essential Strategies

A guide to let you know the different sealing methods of fiber joint closure

Download

Different Sealing Methods for Fiber Splice Closure: 3 Essential Strategies | Top-Quality Structured Cabling & Fiber Solutions by CRXCONEC

Based in Taiwan since 1985, Crxconec Company Ltd. stands at the forefront of fiber cabling technology, offering a broad spectrum of fiber optic network solutions. Our products, ranging from single mode to multi mode fiber cables, fiber patch panels, and distribution boxes, are crafted for optimal performance. Embrace the future of networking with our cutting-edge fiber structured cabling.

At CRXCONEC, we specialize in providing customized cabling solutions to meet your specific business needs. From custom RJ45 keystone jacks to Ethernet and fiber optic cables, our products are designed for flexibility and adaptability. Partner with us for personalized cabling services that align with your unique requirements. Experience the best in fiber-to-home services with CRXCONEC's all-in-one FTTH solutions. Our offerings include high-performance fiber splitters, fast connectors, and fiber adaptors, ensuring seamless home connectivity.

CRXCONEC has been providing customers versatile copper cabling solutions for diverse networking needs, both with advanced technology and 35 years of experience, CRXCONEC ensures that each customer's requirements are met.