What is the component test for the patch cord?

For the copper patch cord, we normally do the performance test by component test or channel test. Here I would like to introduce the difference between the test.

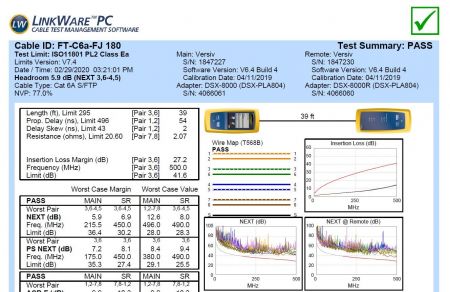

Firstly, about the Component test, it is to test the patch cord itself and must use the Fluke component test adaptor for the test. For the Fluke component test adaptor, the life cycle for the fluke jack is around 5000 times, so the component test cost is higher. The component level patch cord can meet all the channel environment no problem, that is a quality guarantee!

Pls refer to the below picture for component test:

What is the channel test?

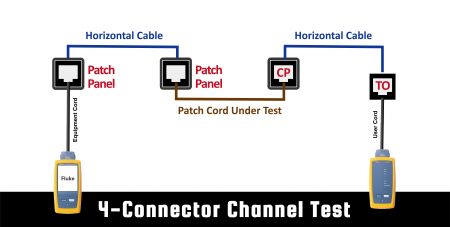

For the channel test, we will set up the 4 connector test environment in our production line. The patch panel and telecommunication outlet (keystone jack) can be provided by our customer or using our standard. A channel link system includes horizontal cable, patch cord, and Keystone Jack. These three components all have an impact on the test results. It’s very difficult to determine which component is the main problem of this link. In this case, we still recommend that you use component test level products to achieve good test results in your cabling projects.

What's the test we'll run for the prodcuts?

We provide copper jumpers of different test levels to meet customer needs, which can build users' confidence in the product and also built the credibility. We also conduct more tests for the products, X-ray machine for thickness of the plating, vertical & horizontal video measurement inspection machines for precision, and automated optical inspection machines directly installed on the automatic machines to examine production line carefully. Let's find out more tests that we do for the products!

- Related VideoRelated ProductsFiles